Overview

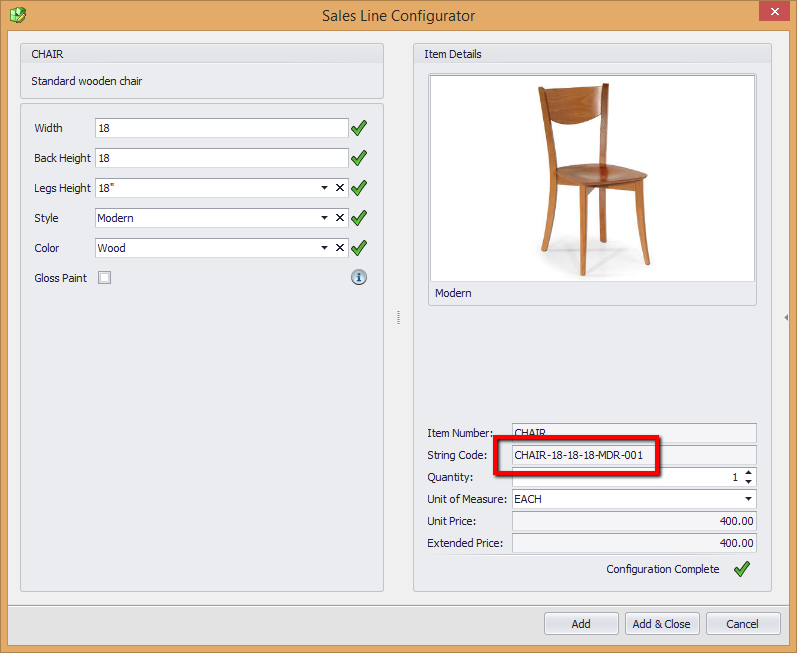

The Configurator is a tool that allows the user to create items that can be configured to customer specifications (i.e. computers, custom t-shirts, furniture, etc.) by selecting the available options (i.e. monitor, hard-drive, color, etc.) when entering an order. Upon order entry, options will be selected and the customer-specified selection will be saved to the relative line item in the form of a string code. The configured items can have items (components) attached to them.

This documents explains how Configurator works in conjunction with Manufacturing. This requires the manufacturing module to be installed in Great Plains, as well as the Manufacturing module/DLL in SalesPad.

Please refer to Configurator documentation for basic description of the Configurator tool and examples of configurations.

Settings, Security, and Setup

Security

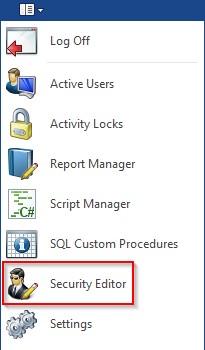

- Go to the Actions dropdown and click Security Editor.

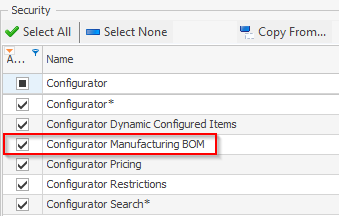

- Search Configurator for all Configurator Securities.

The following Security is required for Configurator Manufacturing.

Configurator Manufacturing BOM – A tab in the Configurator form that allows users to set up details related to Manufacturing Bill of Materials.

Settings

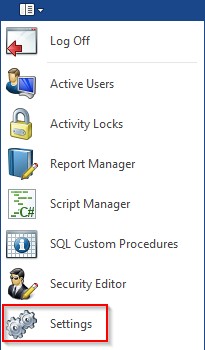

- Click Settings from the Actions dropdown.

- Search Configurator for all Configurator Settings.

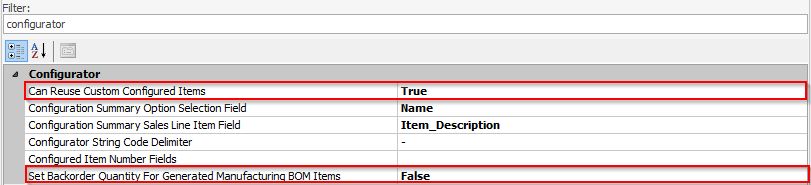

The following Settings are required for Configurator Manufacturing.

Can Reuse Custom Configured Items – If set to True, the Configurator will use Manufacturing BOM and Item Master objects created previously (if any exist for other customers); otherwise Configurator will create new items each time (this requires the Manufacturing module to be installed in SalesPad); defaults to True.

Set Backorder Quantity For Generated Manufacturing BOM Items – It determines whether or not the newly created items are immediately set to backorder when added to the Sales Document. If set to True, it will allow users to create Manufacturing Orders directly from the document (this requires the Manufacturing module installed in SalesPad); defaults to False.

Manufacturing

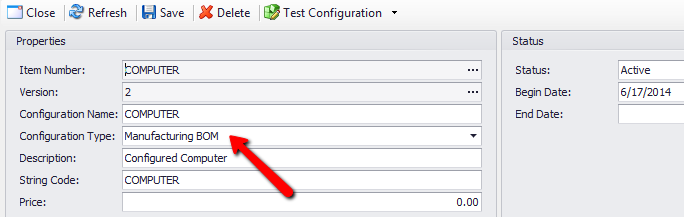

Configurator allows users to create configurations that represent a manufacturing BOM object. In order to do that, set the Configuration Type to Manufacturing BOM.

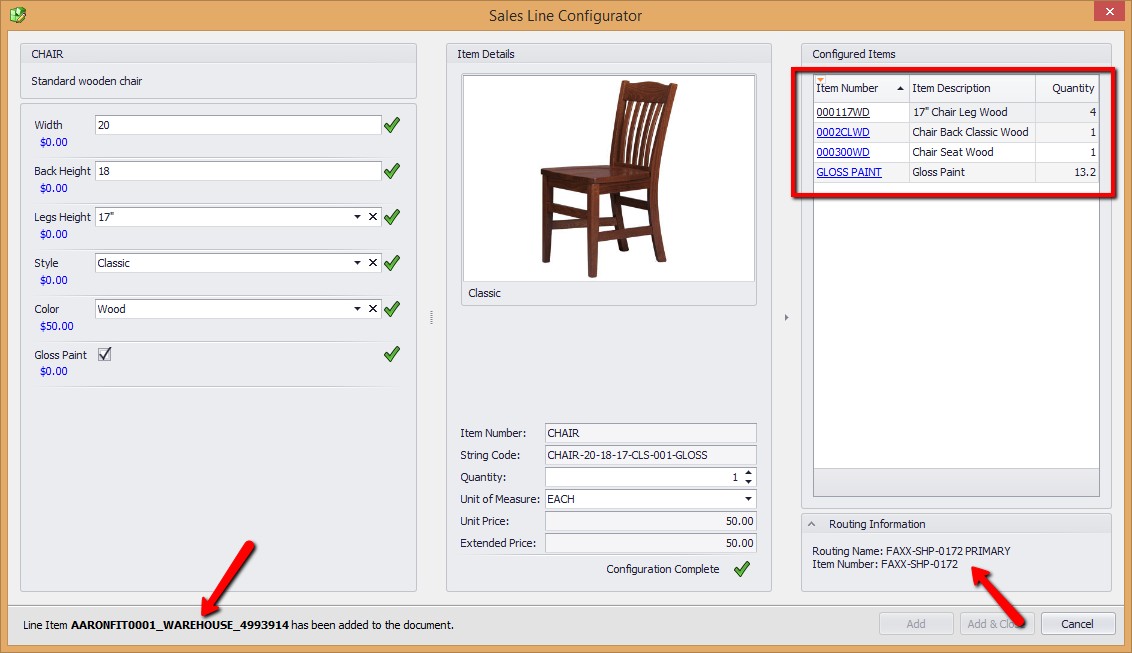

Creating a configured item in a sales order for a configuration that is set to Manufacturing BOM will:

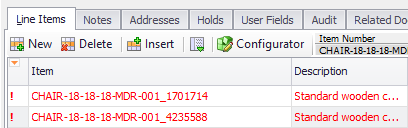

- Create a new item in Dynamics GP, with an auto-generated item number

- The item number generated will depend on the setting Configured Item Number Fields.

- The configuration item (for instance, COMPUTER) will be used as a template for information like unit of measure, sites, etc.

- Create a Manufacturing BOM in Dynamics GP (with the same auto-generated item number)

- The components of the Manufacturing BOM will be the configured items, as shown in the Sales Line Configurator plugin

- Create a Routing Number (with the same auto-generated item number)

- The user will have to specify an existing routing as template

Components Quantity

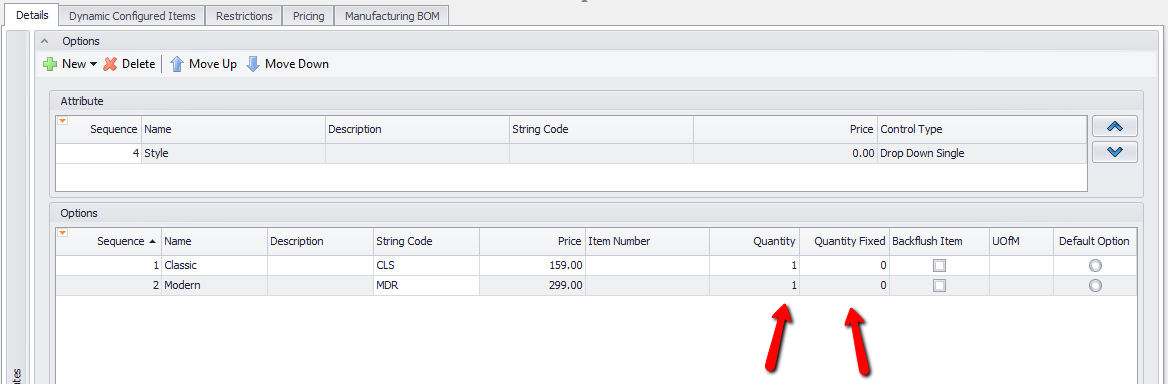

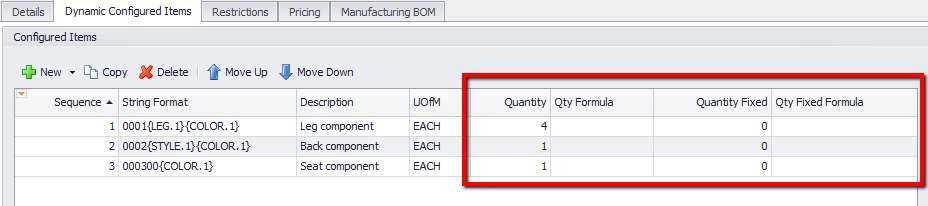

The items that generate the component list for the bill of materials have two types of quantities:

- Quantity: This corresponds to the quantity build in the Manufacturing BOM screen in GP

- Quantity Fixed: This corresponds to the quantity fixed in the Manufacturing BOM screen in GP

Quantity and Quantity Fixed are available in both the Details and Dynamic Configured Items tabs:

Quantity fixed also has the correspondent field Qty Fixed Formula:

Backorder Quantity

The Sales Line Item Configurator plugin can be set to automatically backorder the items through the setting Set Backorder Quantity For Generated Manufacturing BOM Items. Having the items backordered will allow users to create Manufacturing Orders directly from the document (this requires the Create MO plugin from the Manufacturing module in SalesPad).

Routing Information

With the Manufacturing module/DLL in SalesPad, users will also have access to the Manufacturing BOM tab in Configurator (if not visible, turn it on in Security). This tab allows users to set, among other things, the routings information.

Steps to add routing information:

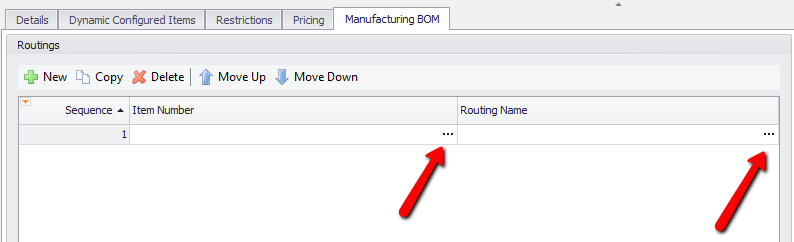

- Select the Manufacturing BOM tab and click New to add a new routing information.

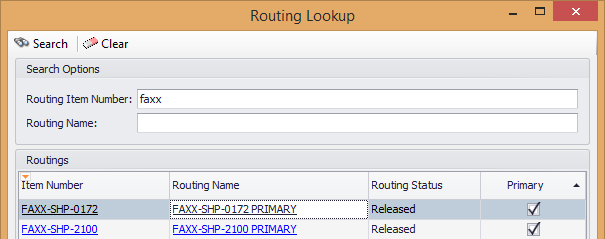

- Type in the Item Number or the Routing Name, or click either ellipsis to load the Routing Search screen.

Note: The Routing Search plugin (from the Manufacturing module) must be enabled in Security. - In the Routing Search screen select the routing information and click OK to add it to the configuration.

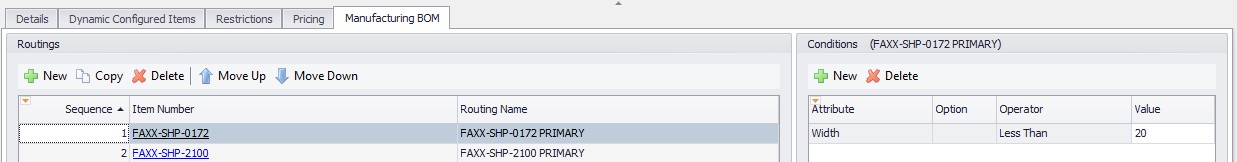

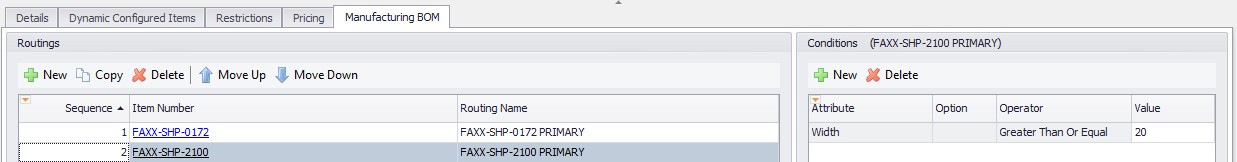

- Users can add multiple routings in your configuration and define conditions to determine which one is picked in the plugin.

The Conditions screen is the same as the one in Dynamic Configured Items tab. See Configurator Advanced, specifically the Configured Items (Components) section for more details.

In the example above, the routing FAXX-SHP-0172 will be selected when the Width is less than 20.

In example above, the routing FAXX-SHP-2100 will be selected when the Width is greater than or equal to 20.

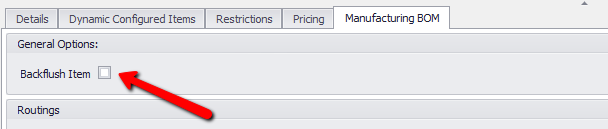

Backflush Option

The Manufacturing BOM tab has the option to backflush all the components in the configuration. Checking the Backflush Item check box in this tab will enable Backflush for all the items in the configuration:

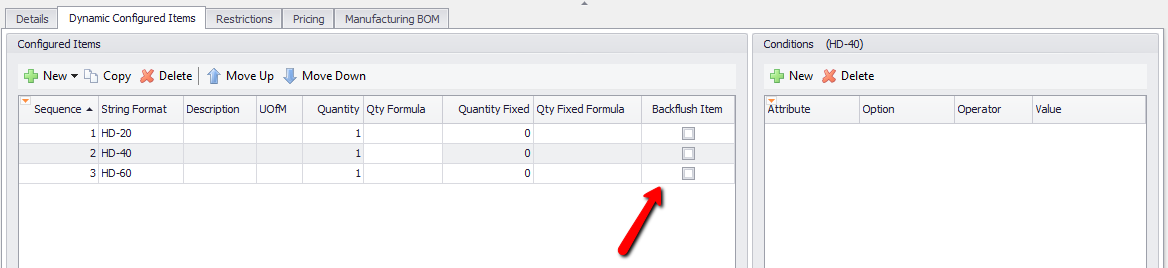

Configurator also allows the user to specify backflush components at the item level:

Custom versus Standard Manufacturing BOM

Configurator treats existing Manufacturing Bill of Materials in two different ways:

- Standard: Manufacturing BOMs manually created in Great Plains or SalesPad

- These items do not have a Configuration ID but they may have Configuration String Code (manually entered in SalesPad by the user).

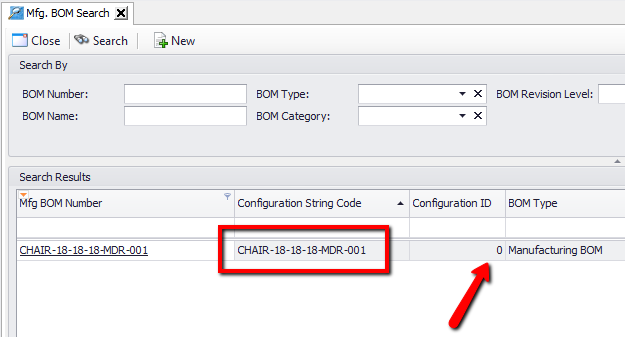

- Custom: Manufacturing BOMs created through Configurator

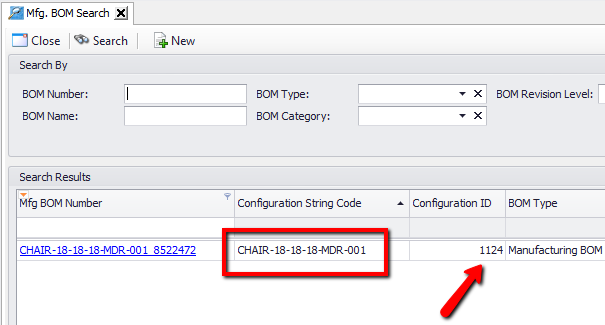

- These items will always have a Configuration ID and a Configuration String Code.

When using configurations as a type of Manufacturing BOM, Configurator may or may not create new Manufacturing BOM items in Dynamics GP, depending on the configuration rules and user settings. These are the four possible outcome scenarios when creating a new configuration from the Sales Line Configurator plugin in a Sales Document:

- If there is an existing standard Manufacturing BOM in Great Plains (with the same String Code as the configuration to be entered by CSR), then Configurator will not create a new BOM; instead, it will add that one in the Sales Document:

- If there is an existing custom Manufacturing BOM (with the same String Code as the configuration to be entered by CSR), and the Setting Can Reuse Custom Configured Items is set to True, the existing configured item will be used in the document.

- If there is an existing custom Manufacturing BOM (with the same String Code as the configuration to be entered by CSR), and the Setting Can Reuse Custom Configured Items is set to False, then Configurator will create a new Manufacturing BOM item:

Note: The resulting item may have a random number at the end in order to differentiate the new items from the existing custom BOMs. - If Configurator does not find a standard or custom Manufacturing BOM with the same String Code as the configuration to be entered by CSR, then it will simply create a new item.

Sub (Nested) Configurations

Configurator will create always one Manufacturing BOM item, even when nesting sub configurations; it does not create separate items for the sub configurations. See Configurator Advanced documentation, specifically section Nested Configurations for more details.

SalesPad Support

Comments