Overview

Inventory Manager (formerly DataCollection) adds a variety of functionality for your iOS or Android device. From the palm of your hand, you can take the power of Inventory Manager and have the following modules at your disposal: Picking, PO Receiving, Packing, Site Transfers, Bin Transfers, Stock Counts, Inventory Adjustments, and Returns. Inventory Manager is designed to support business flows by tracking product inventory in a fast, dedicated, and efficient manner. This guide provides a complete and comprehensive overview to the usage of all Inventory Manager Mobile modules.

Note: The screenshots used in this documentation come from an iOS device. Android users will see slightly different screens, but the functionality is identical.

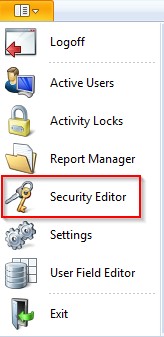

Security

To access Inventory Manager for iOS it must first be enabled in the Security Editor (Modules > Security Editor).

- Go to Security Editor on the Administrative dropdown.

- Turn on the Mobile securities and check the desired securities. It would be wise at this point to enable all mobile securities.

inventory Manager System Requirements

The Inventory Manager System requirements can be found in our System and Hardware Requirements document, located here.

Inventory Manager Android works with select Zebra scanners.

Inventory Manager Mobile Installation

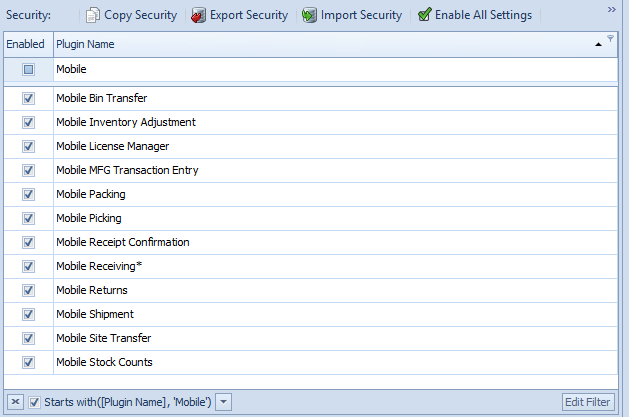

Inventory Manager can be downloaded from the Apple App Store. Below are some instructions on how to download the application:

- Open the Apple App Store.

- In the App Store’s search functionality, search “SalesPad” or “SalesPad Inventory Manager”.

- From the results, select SalesPad Inventory Manager. It is easily recognized by the orange and white barcode logo.

- Select download. When the application finishes downloading and installing automatically, it is ready to be used.

Inventory Manager Mobile Configuration

Inventory Manager Demo

Inventory Manager iOS offers a Demo connection and server setup for users to try out and explore the application and the various transaction modules and their functionality. No additional setup is needed for using the Demo.

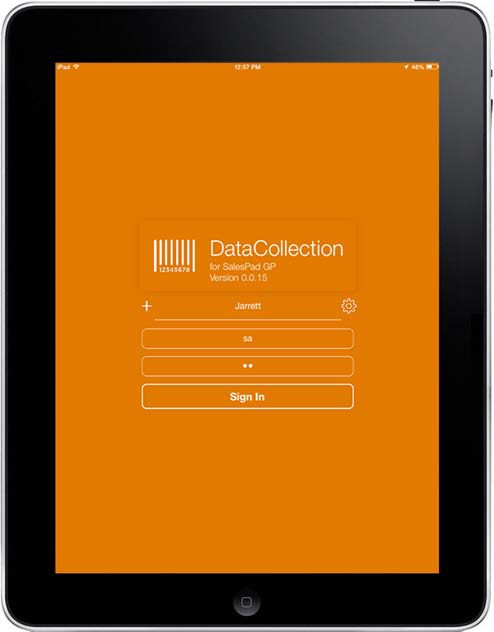

Upon startup of the Inventory Manager application for the first time, the Demo connection will automatically be loaded and set up for use. Additionally, the Demo connection cannot be edited for any reason. The username for the demo connection is simply “salespad” and should be loaded directly into the username field already. If by accident the username field was cleared, it can be re-entered using the virtual keyboard. No password is needed to login to the Demo server, simply select the Sign In button to continue.

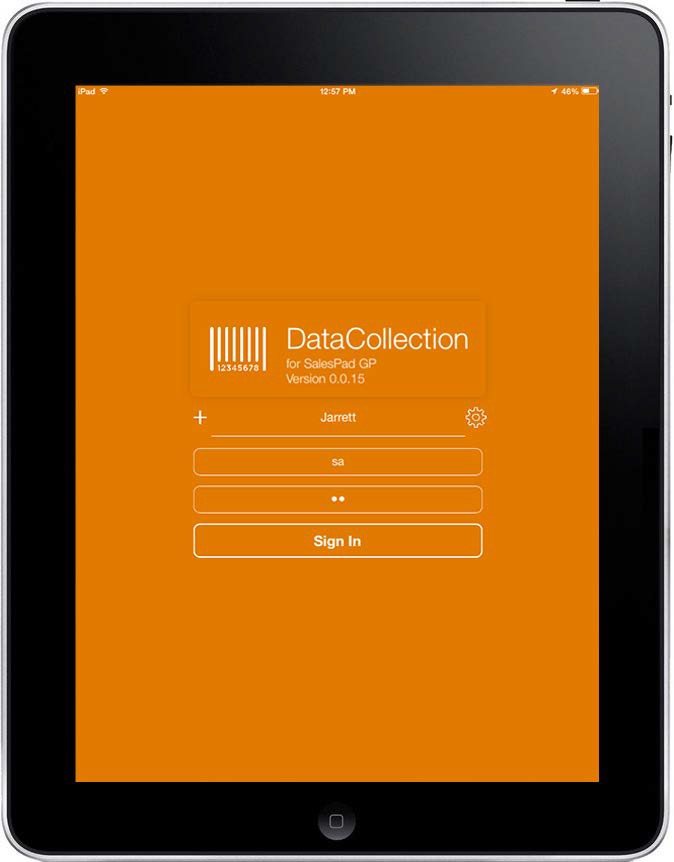

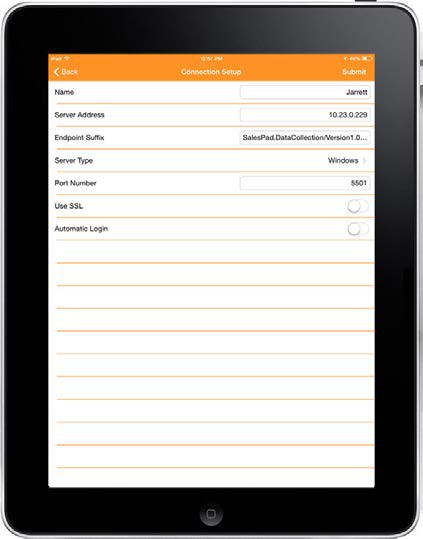

Adding a New Connection

To set up Inventory Manager Mobile:

- From the Inventory Manager sign on screen, tap on the + to add a new connection. This will display the Connection Setup screen. From here, the name of your connection can be specified along with other fields such as Server Address, Server Type, and Port Number. Further explanation of these fields is described below.

- In the Server Address text box, enter the IP address of the server running the Data Collection service followed by the port number (default is 5501).

- For server type select either Windows, IIS, or Custom:

- Selecting the lookup under Server Type tells Inventory Manager to automatically append the default suffix to the server URL for this connection type. Select this option if you are running Inventory Manager service from the Inventory Manager Console.

- Selecting the IIS option tells Inventory Manager not to append a suffix to the server URL for this connection type. Select this option if you are running Inventory Manager service from a website hosted on IIS.

- Selecting the Custom radio button tells Inventory Manager not to modify the server URL in any way. Select custom if you have modified the service URL and it now differs from the default one.

- Tap the Submit button to exit the Connection Setup screen to return to the sign in screen.

- If the details of a connection ever need to be modified, you can do so by pressing the Gear icon to the right of the currently selected connection name. The current connection’s details will open again in a connection setup screen for you to modify as you please.

Use SSL

If the server is configured to use SSL (https), this switch should be on. Otherwise, it should remain off.

Automatic Login

Select this option if you prefer to sign in automatically when the application starts.

Save Password

Select this option if you prefer to allow the application to store the password for the user.

Navigation

Login Screen

To log in to Inventory Manager Mobile, follow the instructions below:

- Between the Add Connection (+ Icon) and Connection Settings (Gear Icon) displays the current Connection Name. (This field will be marked default on first use of the application.) Select the connection you would like to you use.

- Enter the User Name and Password. These fields are case sensitive.

- Tap the Sign In button.

- If the authentication is successful, the Main Menu will display where you can choose one of the inventory transactions available to start working.

Common Error Messages

ConnectFailure (Connection refused) – This connection error can be displayed if the Inventory Manager Server is not running as intended. Verify that the server is on by opening Inventory Manager Console and clicking the Start button under the Inventory Manager Server tab. Also verify the correct port number is entered in the Connection Setup screen on the mobile device.

NameResolutionFailure – Verify that the server address or server name has been entered correctly. Also, check to make sure that your WiFi is on and connected.

Main Menu

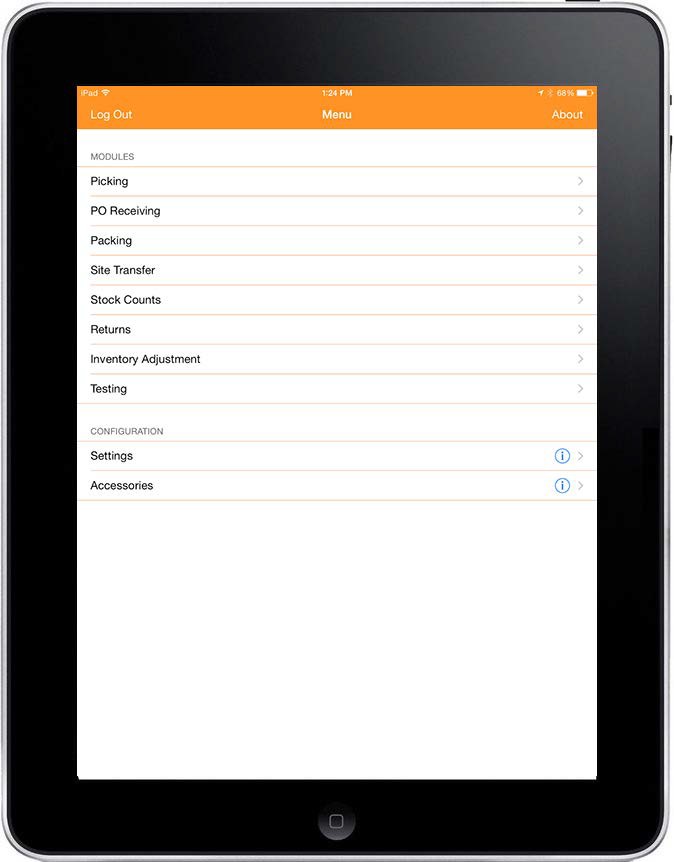

The Main Menu is a central screen from which users navigate to the functions available in Inventory Manager Mobile.

To start a transaction, select from one of the transaction modules available: Picking, PO Receiving, Packing, Site Transfers, Bin Transfers (Multi-Bin only), Stock Counts, Inventory Adjustments, or Returns.

Note: Inventory Manager requires a constant connection to the wireless network. All processes are real-time. SalesPad does not support batch processing (scan a batch of items in a disconnected state and then upload that information at a later time).

Input Types

Inventory Manager offers several ways of inputting data into the various fields all throughout the application. A user can take advantage of the built-in virtual keyboard to enter information. Tapping on any text field within the application opens the device’s virtual keyboard. You may use this tool either as a primary or alternate way of entering data into the application.

Alternatively, users can also select data from respective field lookup buttons, usually located on the right side of each cell within the screen.

Data can be scanned in via mobile scanners and uploaded to the selected fields. Several options exist to help complement scanning as well. Refer to the section labeled Application Accessories for more information on available devices to use in tandem with Inventory Manager Mobile.

Usage

There are a variety of different modules that alter the way Inventory Manager for iOS is used. Below you will find a comprehensive overview of all Inventory Manager iOS modules.

Mobile License Manager

The Mobile License Manager allows users to add licenses for mobile devices on which the Inventory Manager mobile client will be installed. Without this license, the Inventory Manager mobile client will not be able to connect to the IM service.

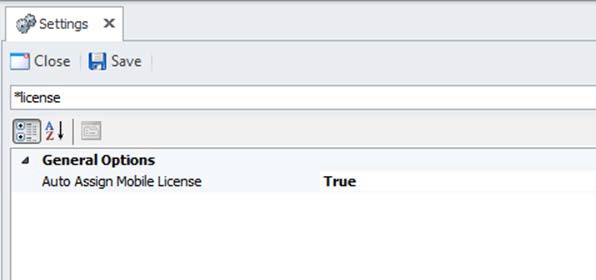

Add License (Automatic)

To allow Inventory Manager to automatically assign licenses when users log in to the IM mobile client, go to Settings in IM Console and set the Auto Assign Mobile License setting to True.

You can view and modify added licenses on the Mobile License Manager screen.

Delete License

Select an existing license you wish to delete and click the Delete button. Click Yes on the resulting confirmation prompt to permanently delete the license.

Edit License

Select an existing license and click the Edit button. The “Mobile License Editor” window will be displayed. Modify the desired values and click OK to save your changes.

Note: That the device ID and module fields are not editable. To change these values, you will need to delete the license entry first and then add it again with new values.

PO Receiving

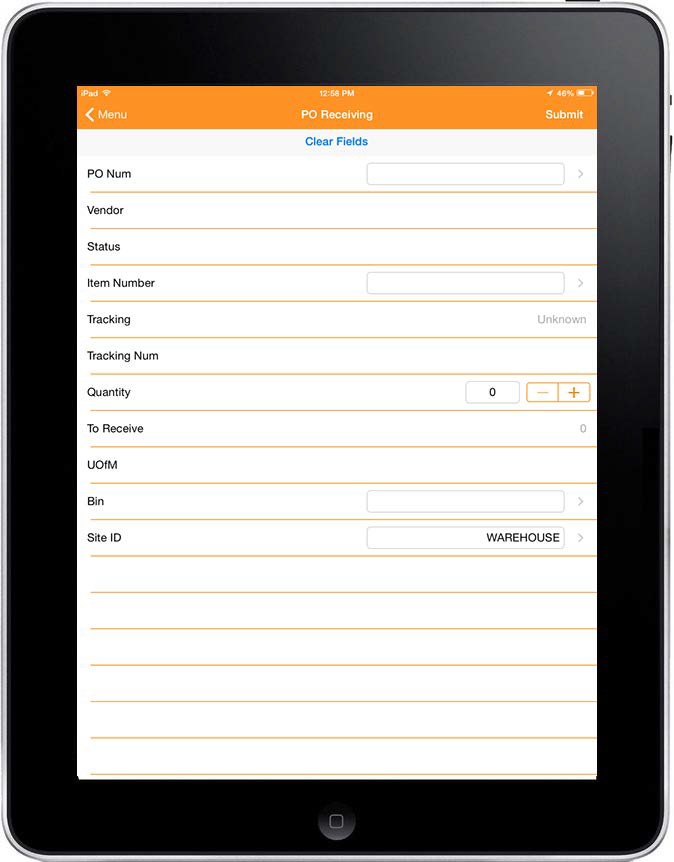

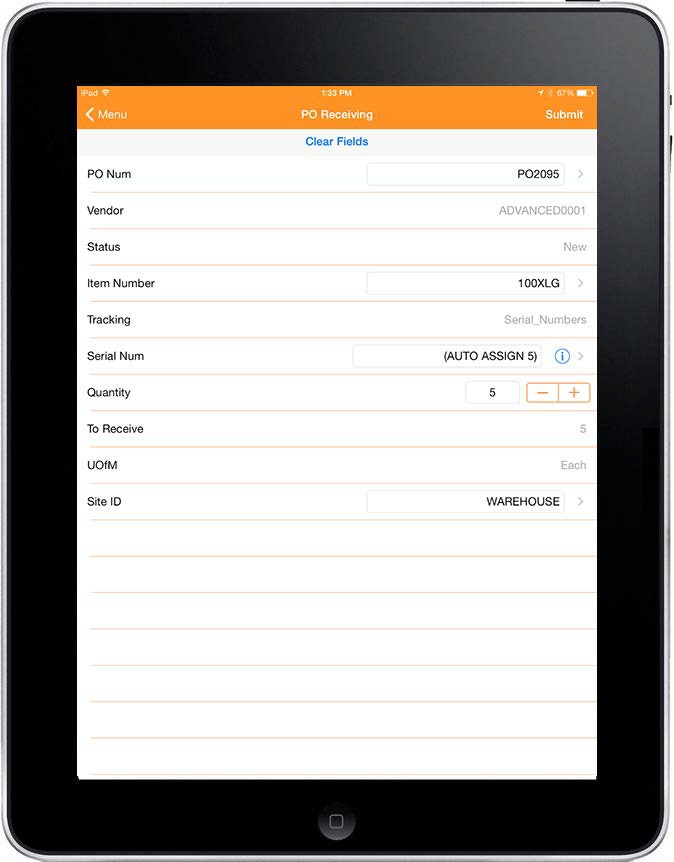

Inventory Manager offers a variety of options for receiving. When you select PO Receiving from the Main Menu, you see the PO Receiving screen shown below. Inventory Manager iOS does not support PO Receiving without a PO number. See the Settings section for more information.

- Scan or enter a purchase order number. You may only receive against a new or released PO.

- Enter an item number in the Item field. You may also tap on the item arrow to look up all the sales line items on that purchase order. Selecting an item number from the lookup list will automatically load it onto the modules main interface.

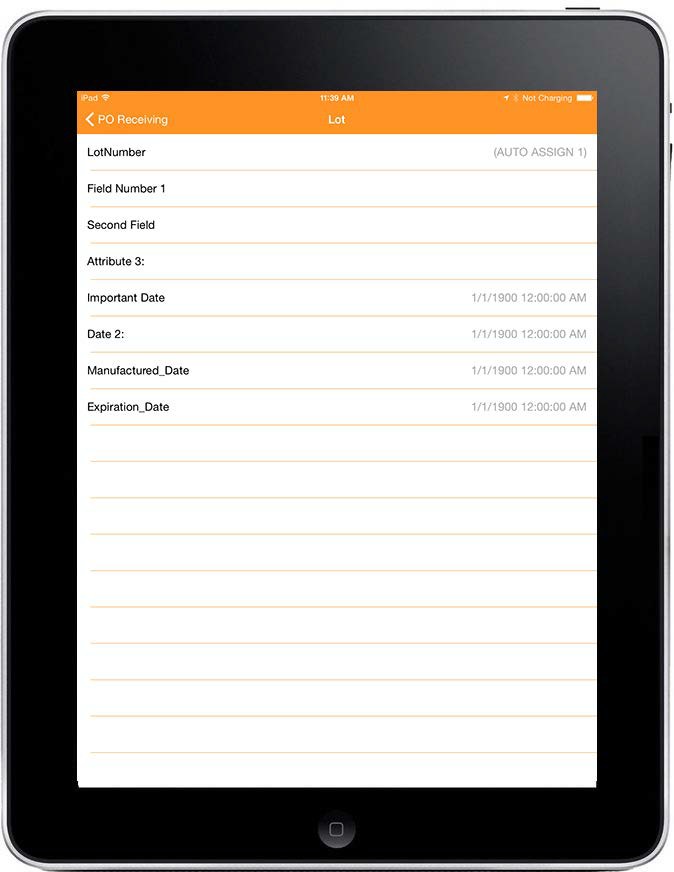

Note: If you have more than one sales line for the same item number, the lookup displays distinct sales lines for those items and they will need to be received separately. - If the item is a lot tracked item, the “Lot” field will appear on the screen:

Tap the lookup to open the Lot Attributes screen, which allows users to view lot attributes including expiration and manufactured dates.

Note: Lot Attributes are set up in Dynamics GP on the Item Maintenance Options screen. - If the item you entered is serial or lot controlled, enter the serial/lot number, otherwise skip that field. You may also generate serial/lot numbers automatically by tapping the Auto button. If you select this option, you will need to enter the number of serials desired and a serial/lot number format depending on your settings. See the section Auto Assign Serial/Lot Number Format for details.

- Enter the quantity. If you enter a quantity higher than the quantity to receive in the sales line item, you’ll be prompted to confirm over-receiving on the item. You may have this field auto-populate every time the screen loads by entering a value in the Default Receiving Quantity setting in the IM Console.

- If GP has the multi-bin option enabled, you will see the bin field on the screen. Enter the bin to receive against. You may also tap on the lookup arrow to find all the bins on that site. Select the bin desired.

If the bin you entered does not exist but you have the setting Allow Bin Creation enabled in the IM Console, the application will automatically create that bin for you. To add a bin in this fashion, simply enter the name of your new bin in the text field manually. - Enter the site you want to receive against. You may auto populate this field every time the screen loads by entering a warehouse in the Default Warehouse setting in the IM Console.

- Tap the Submit button to finish.

- Repeat steps 2 though 7 until the PO is fully received. When the purchase order is fully received, a message will appear at the top of the screen informing the user and displaying the receipt number.

Note: If you make a mistake while entering data or if you scanned the wrong bar code, you may backspace on that field and correct your data. The Clear button clears all fields on the form. The list of fields to clear may be adjusted in the IM Console via the setting Receiving Fields To Clear.

Note: Inventory Manager Mobile does not post any transactions in Dynamics GP. Users must post the receipt manually.

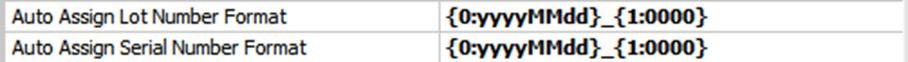

Auto Assign Serial/Lot Number Format

You may specify the format of the serial/lot numbers used during the automatic generation process.

In the Inventory Manager Console, click on the Settings button in the toolbar and find the two settings below in the miscellaneous section.

The default format is “{0:yyyyMMdd}_{1:0000}” which adds the system date in yyyyMMdd format as a prefix to the auto incrementing number. You may change this format number to fit your needs.

If you set any of these settings to manual, you may enter the number format during the receipt by tapping the Auto button in the serial/lot field. If you prefer to use Dynamics GP number formats you may set these settings to blank. During the receipt, you only need to enter the number of serials to generate and skip the format text box.

Note: If you adjust settings in Inventory Manager Console, you will need to log out of both the console client and mobile application and log back in before the changes can take effect. Before logging out, any changes must be saved on the console.

PO Receiving Settings

Adjust the following Inventory Manager Console settings as necessary. Save any changes you make in Inventory Manager Console and log back in to both the console and mobile application for changes to take effect.

PO Receiving General Settings

Auto Generate Lot Numbers Format - Sets the format of the auto generated lot numbers created during receiving on Inventory Manager Console.

Auto Assign Serial Number Format - Sets the format of the auto generated serial numbers created during receiving on Inventory Manager Console.

Can Over Receive - When set to True, the user can receive items even when the quantity to receive is greater than the quantity ordered.

Default Receiving Batch - A value used to determine the default batch during receiving.

Default Receiving Bin - A value used to determine the default bin during receiving.

Group Receipt Lines - When set to False, a new receipt line will be created every time new quantity is received for the same item.

Prompt When Over Receiving - When set to True, Inventory Manager prompts the user to allow or prevent over receiving when the quantity received exceeds the quantity ordered.

PO Receiving Scanner Settings

Allow Auto Generate Serial Lot - Determines whether the auto-generate button will be enabled on the scanner on Receiving and Inventory Adjustment. Set this to False if you’re using serials or lots that are generated outside of Dynamics and you need the users to scan the values in when receiving.

Allow Item Lookup Selections As Scanned Receipt Items - If set to True, the quantity field will be incremented when the user selects an item through the lookup screen when the setting Increment By Scan is enabled.

Auto Generate Bin Numbers - Creates bin numbers if the bin is empty based on the Auto Generate Bin Numbers Format setting.

Auto Generate Bin Numbers Format - The layout of the bin numbers that will be auto generated. Defaults to an incrementing integer with an Auto prefix. (ex Auto:100)

Auto Submit Receipts - If enabled, this setting allows serial/lot numbers to be auto-generated and receipts to be automatically submitted when the PO number and item number are entered.

Catch Weight Separation Character - Specify a character that will separate the lot number and weight when receiving catch weight items.

Clear Bin On Submit - Clears the Bin field on submit.

Client Auto Assign Lot Number Format - Sets the format of the auto generated lot numbers created during receiving using Inventory Manager on a handheld scanner.

Client Auto Assign Serial Number Format - Sets the format of the auto generated serial numbers created during receiving using Inventory Manager on a handheld scanner.

Default Receiving Quantity - The number that will default into the quantity text box on the receiving screen when using the handheld scanner.

Enable Classic Receiving - When set to True, the handheld receiving screen will skip the receipt header screen and go directly to a PO Receiving screen like older version of Inventory Manager. Receipts generated with this enabled will be Shipment Receipts.

PO Lookup Cutoff Date - Enter the PO date field that specifies which date to use as a cutoff during PO Lookups. The options are: Promised_Ship Date, Promised_Date, Required_Date.

PO Lookup Date Range - Enter the number of days to use as date range criteria during PO Lookups. The value sets both the number of days in history that the search will go back and the cutoff date.

Receipt Types Allowed - Defines a list of Receipt Types that will be allowed in Receiving. Currently, Shipment and Shipment Invoice are the only supported Receipt Types. This setting is used to populate the Receipt Types lookup on the Receipt Header screen for Receiving; Enable Classis Receiving must be false.

Receiving Increment By Scan - If set to True, the quantity field in the Receiving screen will be disabled and the quantity will be calculated/incremented by the number of individual items scanned. This setting cannot be used when the setting Suggest Next Item To Receive is enabled.

Receiving Pre Submit Script - Receiving C# script that executes when the Submit button is clicked before the transaction is saved.

Receiving Post Submit Script - Receiving C# script that executes when the Submit button is clicked after the transaction is saved.

Require Bin On Submit - If set to True, users are required to enter a value in the Bin field when they submit the transaction.

Require PO On Submit - When True, the receiving screen will require a Purchase Order number in order to receive items.

Reuse Auto Generated Bin Numbers – Allows each mobile device to reuse the last bin number it generated.

Suggest Next Item To Receive - If enabled, suggests the next item to receive in the order in which it is listed on the sales document. Upon tapping Submit, IM Mobile automatically loads the next item to the item number field.

Use PO Number As Receipt Batch - If True, batch names will match the receipt number. If False, all receipts will be in the same batch.

General Settings

Default Warehouse - Enter the name of the desired warehouse to pre-populate the warehouse field in all IM Mobile transactions when the screen loads

Force Rescan - If set to True, IM forces users to rescan item numbers for verification purposes. The item number will clear after the first scan and the item must be rescanned to be accepted as a valid entry to allow the user to continue the transaction. When set to False, the item number will be accepted the first time it is scanned

Screen Setup Settings

Receiving Field Sequence - See Changing the Field Sequences under Additional Settings

Receiving Fields To Clear - See Modifying the Fields to Clear under Additional Settings

Receiving Select Field Sequence - See Changing the Field Sequences under Additional Settings.

Receiving Select Fields To Clear - See Modifying the Fields to Clear under Additional Settings.

Bin Transfers

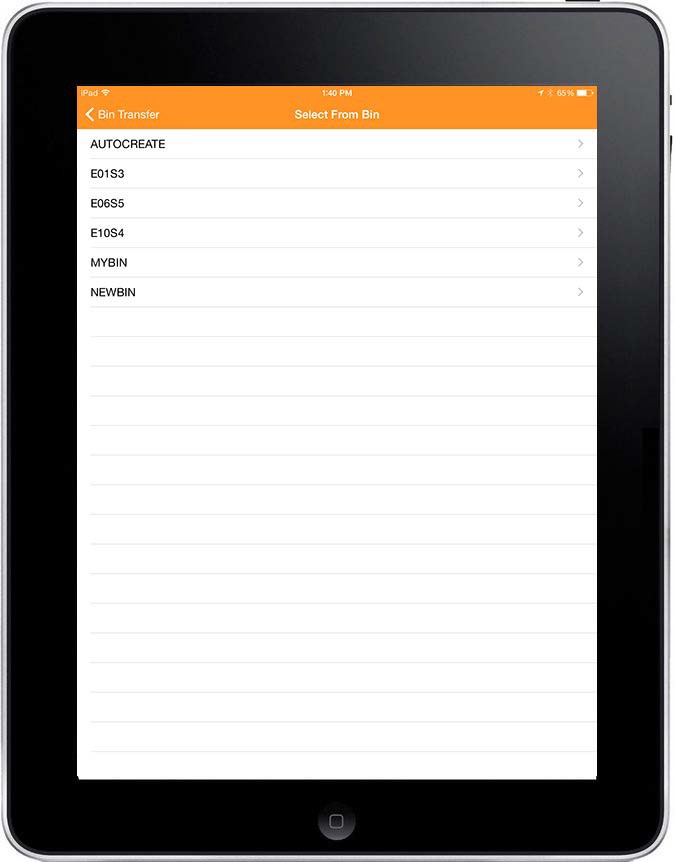

The Bin Transfer screen allows users to move merchandise to other bins located in the same site. To transfer items to another bin, follow the steps below:

Note: Bin Transfers is only supported if the Multi-Bin option is enabled in Dynamics GP. If this setting isn’t enabled, the Bin Transfers screen will not appear as one of the options in the Inventory Manager main menu screen.

- Scan the item or enter the item number manually.

- If the item you entered is serial or lot controlled, additional fields below the item number will populate to display the proper tracking information related to the item. For example, if the item is serial tracked, the Tracking field will display Serial_Numbers and immediately below that field will be a lookup field for assigning serial numbers to the item. If the item is neither serial nor lot tracked, Tracking will display None.

- Enter the bin you are transferring the item from. You may also tap on the lookup arrow to see all bins containing the item. You may also enter the site for more precise searches. Select the bin desired.

- Enter the bin you are transferring the item to. You may use the lookup arrow here as well. If the bin you entered does not exist but you have the setting Allow Bin Creation enabled in the IM Console Settings, the application will automatically create that bin for you.

- Enter the quantity and select the unit of measure from the lookup arrow.

- If applicable, you can enter or view notes in the Note field.

- Tap the Submit button.

Respective Transactions

The following validations are performed when data for the transfer is entered, before the transaction is submitted:

- Site: By default, this field will be set to the warehouse established in the setup. If the lookup arrow is clicked, validation is run to gather all available sites. No validation is performed for Site IDs manually entered.

- From: If the lookup arrow is clicked, validation is run to check for bins within the site selected. However, an invalid From Bin can be manually entered.

- Item: Verifies the item number is not blank

- S/L: When manually entering S/Ls: verifies that duplicated serials are not entered. When the

is clicked: verifies serials exist for the item number entered.

is clicked: verifies serials exist for the item number entered. - To: If the lookup arrow is clicked, validation is run to check for bins within the site selected. However, an invalid To Bin can be manually entered.

- Qty: Verifies that a number/decimal is entered

- Note: No validation performed

Once the transfer is submitted, the following fields are validated:

- Item number is checked for existence

- If the From Bin is the same as the To Bin, the transfer will not be completed

- To Bin is checked for existence

- Serial / lot is checked for validity

Bin Transfer Settings

Below describes Bin Transfer and General Settings for Bin transfers. Adjust these settings as necessary. Save any changes you make in Inventory Manager Console and log back in to both the console and mobile application for changes to take effect.

Bin Transfer Scanner Settings

Allow Item Lookup Selections As Scanned Transfer Items – If set to True, the quantity field will be incremented when users select and item through the lookup screen when the setting Increment By Scan is enabled.

Auto Submit Bin Transfers – If set to True, the bin transfer transaction will auto submit after entering all data in the scanner.

Default Bin Transfer Quantity – The quantity that will default into the quantity text box on the bin transfer screen. Use Max to use the full bin quantity.

Default Transfer To Bin – The default bin used for bin transfers.

Increment Quantity By Scanning Transferred Item – If set to True, the quantity field in the Bin Transfers screen will be disabled and the quantity will be calculated/incremented by the number of individual items scanned.

Shows Item Bins Only In the To Bin Lookup for Bin Transfers – If set to True, the To Bin lookup query results will only display the bins where the item has inventory for bin transfers.

Bin Transfer General Settings

Bin Transfer Field Sequence – See Changing the Field Sequences under Additional Settings.

Bin Transfer Fields To Clear – See Modifying the Fields to Clear under Additional Settings.

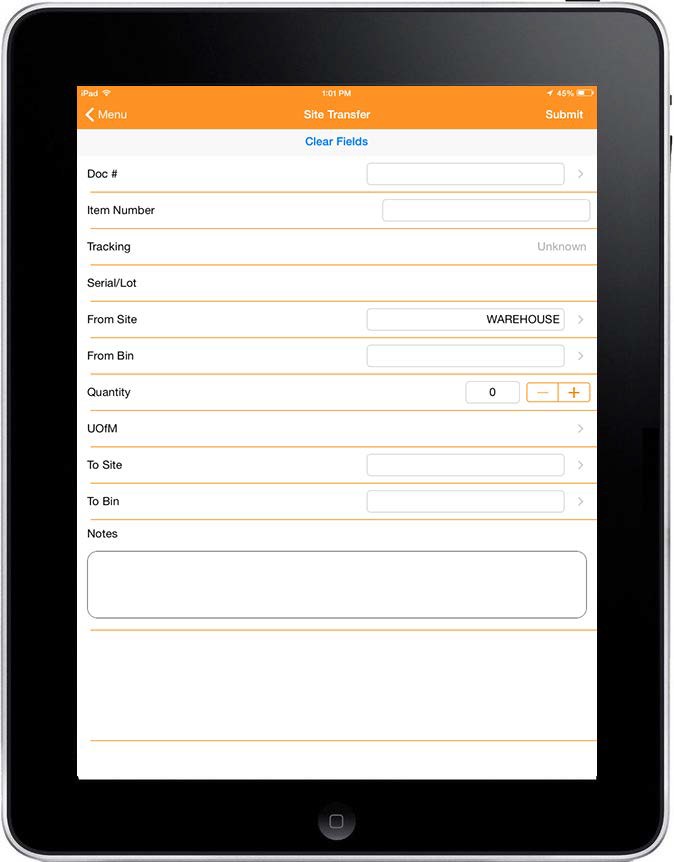

Site Transfers

The Site Transfer screen allows users to transfer merchandise to different warehouses. To transfer items to another site, follow the steps below:

- If you are starting a new transfer document, leave the document field blank. Otherwise, enter the document number you want to edit. You may use the lookup arrow to find open transfer documents.

- Scan or enter the item number.

- Enter the warehouse you are transferring the item from. You may also tap on the lookup arrow to find all warehouses containing the item. You may also enter the warehouse for more precise searches.

- Enter the bin you are transferring the item from. You may use the lookup arrow here as well.

- If the item you entered is serial or lot controlled, enter the serial/lot number, otherwise skip that field.

- Enter the quantity and select the unit of measure from the lookup arrow.

- Enter the warehouse you are transferring the item to. You may also tap on the lookup arrow.

- Enter the bin you are transferring the item to. You may use the lookup arrow here as well. If the bin you entered does not exist but you have the setting Allow Bin Creation enabled in the IM Console Settings, the application will automatically create that bin for you.

- You can optionally add notes in the Note field. Notes can be viewed from this field.

- Tap the Submit button.

Note: To make a successful transfer, the quantity being transferred must be on hand and unallocated in the From Site

Site Transfer Settings

Below are the Settings for Site Transfers. Adjust these settings as necessary. Save any changes you make in Inventory Manager Console and log back in to both the console and mobile application for changes to take effect.

Site Transfer Scanner Settings

Shows Item Bins Only In the To Bin Lookup for Site Transfers - If set to True, the To Bin lookup query results will only display the bins where the item has inventory for site transfers.

Site Transfer Document Lookup Batch – In the Site Transfers screen, the document lookup will only display the site transfer documents matching the specified workflow batch. If this setting is left blank, the lookup will not filter by workflow batch.

Site Transfer General Settings

Site Transfer Field Sequence – See Changing the Field Sequences under Additional Settings.

Site Transfer Fields To Clear – See Modifying the Fields to Clear under Additional Settings.

Shows Item Bins Only In The To Bin Lookup – If True, the To Bin lookup query results will only display bins where the item has inventory. If the item number is not entered, the lookup will display all bins.

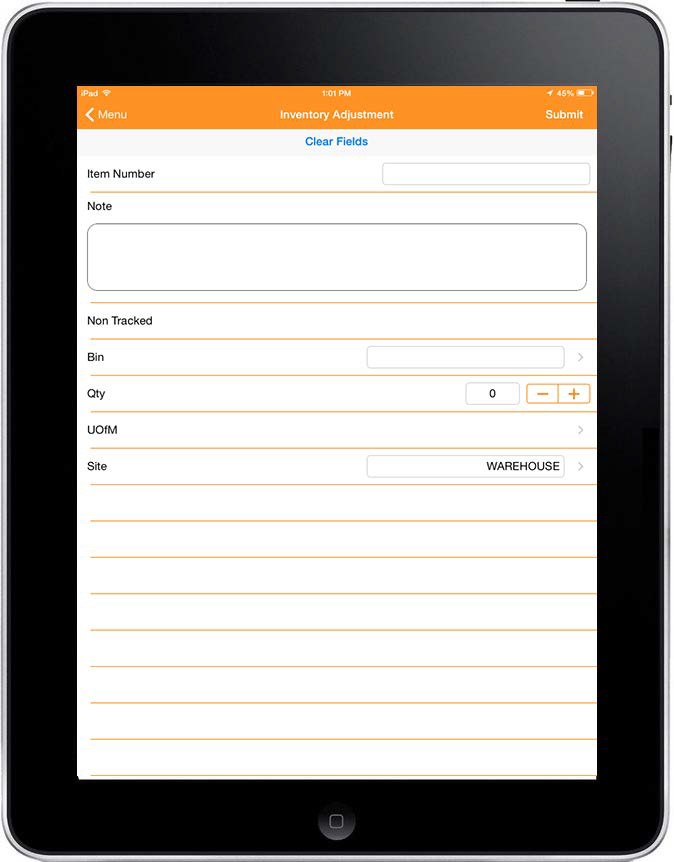

Inventory Adjustments

The Inventory Adjustments screen allows users to increase or decrease the quantity of available inventory. To make an Inventory Adjustment, follow the steps below:

- Scan or enter the item number to be adjusted.

- If the item is a lot tracked item, the Lot field will appear on the screen (if not, skip this step): Tap the arrow lookup to open the Lot Attributes screen, which allows users to view and add/change lot attributes including expiration and manufactured dates, etc.

- If the item you entered is serial or lot controlled, additional fields below the item number will populate to display the proper tracking information related to the item. For example, if the item is serial tracked, the Tracking field will display Serial_Numbers and immediately below that field will be a lookup field for selecting serial numbers to the item. If the item is neither serial nor lot tracked, Tracking will display None.

- Enter the Quantity and unit of measure. Tap either the + or - buttons in the quantity field to indicate if the transaction will increase or decrease inventory (- will reduce; + will increase).

- Enter the bin location where the adjusted item is located. You may also tap on the lookup arrow to view up all bins containing the item.

- Enter the site where the adjusted item is located. You may also use the lookup arrow.

- If applicable, you can enter or view notes in the Note field.

- Tap the Submit button.

Inventory Adjustment Settings

Below are the Settings for Inventory Adjustments. Adjust these settings as necessary. Save any changes you make in Inventory Manager Console and log back in to both the console

Inventory Adjustment Scanner Settings

Inventory Adjustment Allow Bin Quantity Override - When enabled, the quantity to adjust will be allowed to override the quantity allocated for non-tracked items.

Inventory Adjustment Batch Format - Defines the format of the batch number to be used for Inventory Adjustments created from the mobile scanner

Inventory Adjustment Post Submit Script - Inventory Adjustment C# script that executes when the submit button is clicked after the transaction is saved.

Inventory Adjustment Pre Submit Script - Inventory Adjustment C# script that executes when the submit button is clicked before the transaction is saved.

Require Reason Code on Inventory Adjustment - Requires the user to select a Reason Code before submitting an inventory adjustment

SalesPad Support

Comments