Overview

A Routing is the process that is to be taken when creating an item with the Manufacturing process. Each Routing has a defined number of sequences for the Manufacturing Order.

Security

Routing Entry

- Can Edit : True/False - Determines if a user has permission to edit Routing Details.

Scripts

- On Load Script - Script that executes before a Routing is loaded.

- Pre Save Script - Script that executes before a Routing is saved.

Routing Search

Routing Details Search

Routing Detail User Fields

- Allow Layout Customization: True/False - Determines if a user has permission to edit the User Field layout.

- Read Only: True/False - Determines if a user has permission to edit User Fields.

- Routing Mass Update

- Routing Mass Add Details

- Routing Details Mass Update

- Routing Details Mass Delete

- Routing Details Mass Update

- Manufacturing Routing Lookup

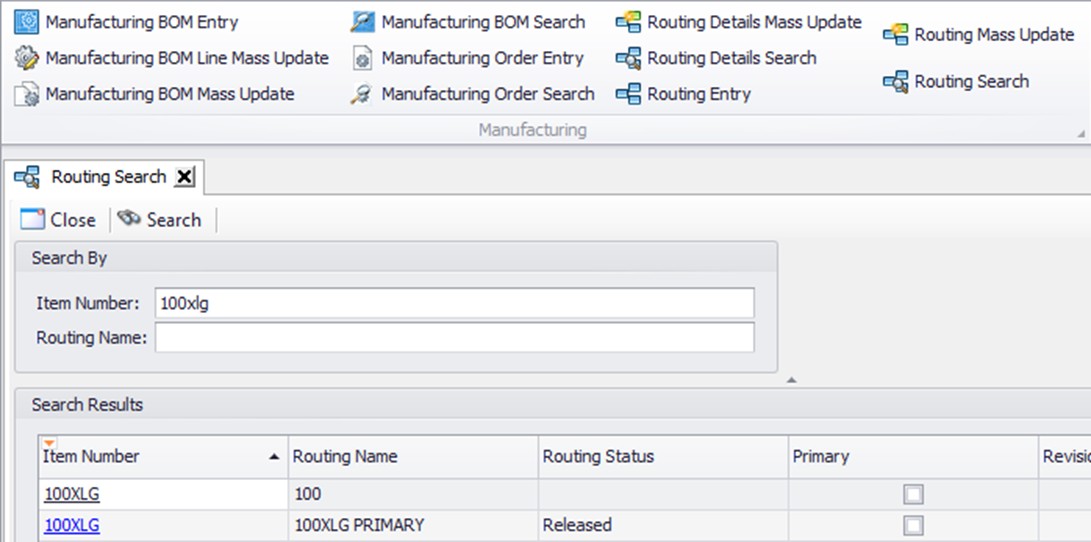

Routing Search Screen

The Routing Search is found on the ribbon menu across the top of the SalesPad window, on the Manufacturing tab. Here, the user can search for existing Routings by any part of a keyword in the Item Number, or by the Routing Name. Opening any of the Routings will open the Routing Details Entry Screen, as seen below.

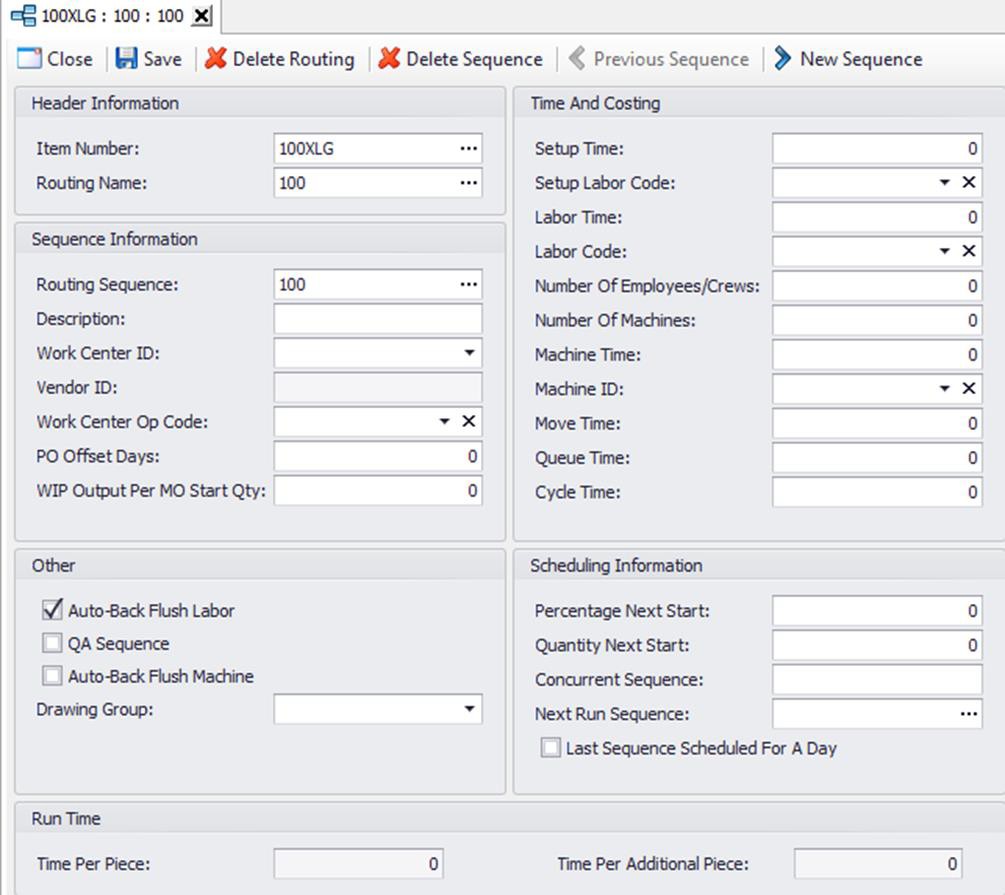

Routing Details Entry

From the Routing Details Entry Screen, users can modify, and delete existing Routing Sequences, and add new Routing Sequences.

Item Number: This is the inventory item that can use this routing.

Routing Name: This is a unique name for this routing. Multiple routings with different names can be made for the same Item.

Routing Sequence: This is the unique sequence in the routing. Sequences are consecutive, and are govern the workflow of the manufacturing process.

Work Center ID: This is the work center at which this sequence of the routing takes place.

Vendor ID: Displays the identifier of the vendor associated with an outsourced work center.

Work Center Op Code: Operation code for the sequence. Selecting an Op Code will default in some fields

PO Release Offset Days: The number of days the purchase order for outsourced services should be released before the vendor will need to begin working on the outsourced sequence.

WIP Output Per MO Start Qty: The number of items per finished item expected from this sequence.

Auto-Back Flush Labor: Labor costs for this sequence should be calculated using the standard routing times when the manufacturing order is closed or items from the manufacturing order are received.

QA Sequence: The sequence is part of a quality assurance program.

Auto-Back Flush Machine: Machine costs for this sequence should be calculated using standard routing times when a manufacturing order is closed or items from the manufacturing order are received.

Drawing Group: Displays the drawing group that includes any electronic file attached to the routing sequence.

Setup Time: The hours required to prepare the work area for this sequence.

Setup Labor Code: The labor code required of the person completing the setup tasks.

Labor Time: The hours required for an employee to complete this sequence for one item.

Labor Code: The labor code required of the person completing the sequence tasks.

Move Time: The hours required to move an item to the location for the next sequence.

Queue Time: The number of hours that items must wait before beginning this sequence.

Cycle Time: Number of hours required for each unit in this sequence.

Percentage Next Start: The percentage of the total items in a manufacturing order that needs to be complete before the next sequence can begin.

Quantity Next Start: The number of the total items in a manufacturing order that needs to be complete before the next sequence can begin.

Concurrent Sequence: A parallel sequence that can be run at the same time as this one.

Next Run Sequence: The sequence number of the next sequence to be completed after this sequence. Used for concurrent sequencing.

Time Per Piece: The amount of time needed to produce one piece, including setup time.

Time Per Additional Piece: The amount of time needed to complete this sequence for the second and subsequent pieces.

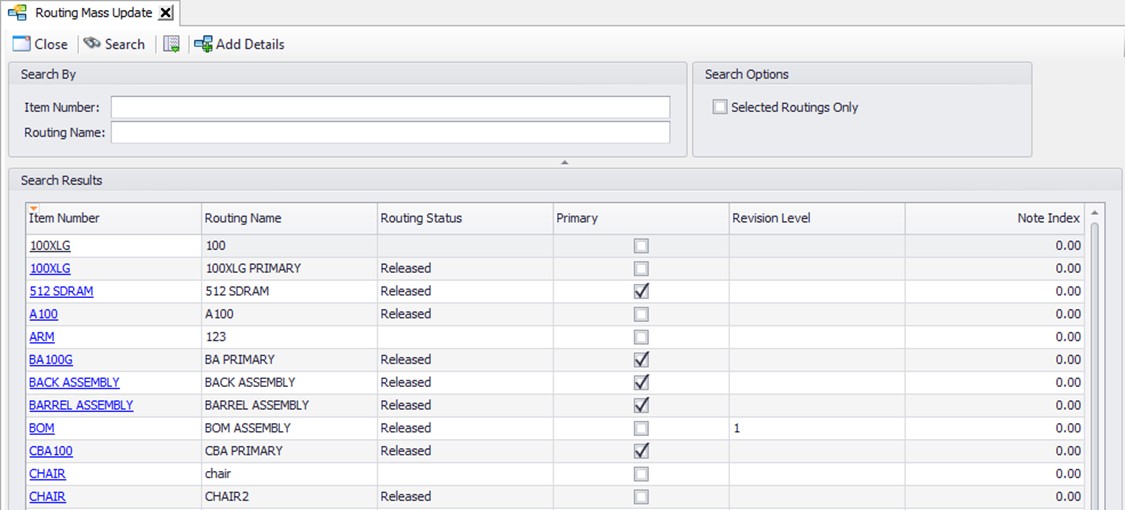

Routing Mass Update

The Routing Mass Update is found on the ribbon menu across the top of the SalesPad window, on the Manufacturing tab.

Here, the user can search for existing Routing and add a sequence to many routings at once.

If the Selected Routings Only checkbox is not checked when running the Add Details plugin, all lines that are manually selected in the search result will have the routing sequence added. It is possible to manually select/deselect more than one routing by holding down Ctrl and clicking a row.

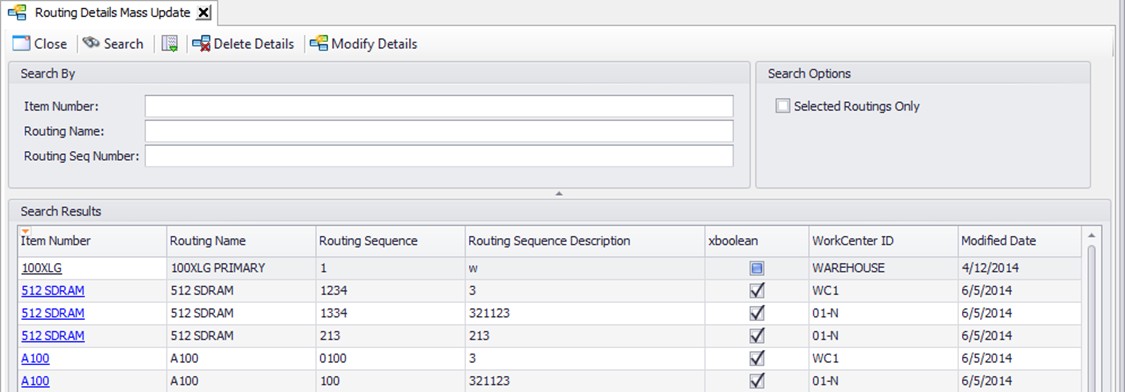

Routing Details Mass Update

The Routing Details Mass Update is found on the ribbon menu across the top of the SalesPad window, on the Manufacturing tab.

Here, the user can search for existing Routing and add a sequence to many routings at once.

If the Selected Routings Only checkbox is not checked when running the Routing Mass Delete Details plugin, all sequences in the search result will be deleted.

If the Selected Routings Only checkbox is checked when running the Routing Mass Delete Details plugin, all sequences that are manually selected in the search result will be deleted.

If the Selected Routings Only checkbox is not checked when running the Routing Mass Modify Details plugin, all sequences in the search result will be modified.

If the Selected Routings Only checkbox is checked when running the Routing Mass Modify Details plugin, all lines that are manually selected in the search result will be modified.

SalesPad Support

Comments